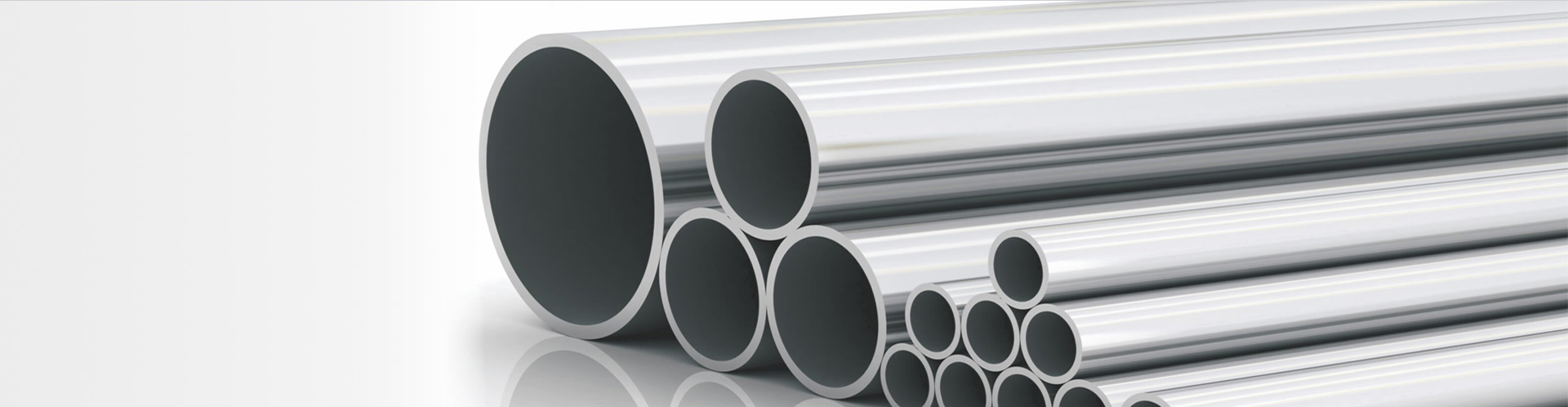

Shape: Round bar, flat bar, sheet

Grade: H3, H13, H11, H21

Wuxi Gotele Metal Corporation supply a wide range of quality tool steel,

such as H3, H13, H11, H21 etc, which are highly acclaimed by our international customers

due to its durability and similar other attributes

Manufacturing of Tool Steel Bar:

- Cold rolling, slitting and edge processing

- Heat treatment: annealing, tempering, hardening

- Cold finishing and polishing

Heat Treatment:

Normalizing:

Normalizing temperature: 860-900oC.

Soft Annealing:

Heat to 760-800oC, cool slowly in furnace.

This will produce a maximum Brinell hardness of 217.

Stress Relieving:

Stress relieving to remove machining stresses should be carried out

by heating to approx. 650oC, holding for 1-2 hours at heat,

followed by air cooling. This operation is performed to reduce distortion during heat treatment.

Hardening:

Harden from a temperature of 830-890oC followed by oil quenching.

Hardness after quenching is approx. 64 HRC.

Tempering:

Tempering temperature: 150-180oC.

Specification of Tool Steel:

Packaging of Tool Steel Bar:

Wuxi Gotele Metalare packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

Feature of Tool Steel Bar:

- High fatigue resistance

- Good plasticity in cold condition

- High quality with competitive price

- Good combination property?